Mitsubishi’s engineering heritage spans decades of innovation, from rally-dominating turbocharged four-cylinders to efficient naturally aspirated engines powering economy vehicles worldwide. The company’s reputation for producing robust, technologically advanced powerplants makes Mitsubishi vehicles popular among enthusiasts and practical buyers alike. Understanding engine replacement options when these reliable engines eventually require service helps owners maintain performance while managing costs effectively.

Mitsubishi’s Engine Legacy

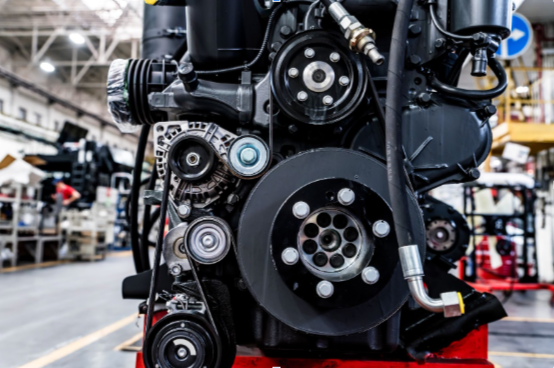

Mitsubishi earned legendary status through engines like the 4G63, which powered everything from Lancer Evolutions to Eclipse GSX models. This turbocharged four-cylinder’s ability to handle substantial power increases with relatively modest modifications made it an enthusiast favorite. The 4G63’s robust bottom end, efficient turbocharger integration, and responsive engine management created a platform capable of everything from daily driving to competition use.

The 6G72 V6 series provided smooth, reliable power across Mitsubishi’s larger vehicles. Available in naturally aspirated and twin-turbocharged variants, these engines delivered impressive performance while maintaining reasonable fuel economy and longevity with proper maintenance. The 3000GT VR-4’s twin-turbo 6G72 represented technological sophistication rarely seen in 1990s production vehicles, featuring all-wheel drive, active aerodynamics, and adjustable suspension alongside its powerful engine.

More recent Mitsubishi engines, including the 4B11 and 4B12 series, incorporate modern technologies like MIVEC variable valve timing while maintaining the durability and efficiency that built the brand’s reputation. These aluminum-block engines reduce weight while providing adequate power for compact and mid-size vehicles. Though perhaps less celebrated than earlier performance engines, modern Mitsubishi powerplants offer excellent reliability and fuel economy for everyday transportation needs.

Common Issues and Maintenance Requirements

Mitsubishi engines generally prove reliable with appropriate maintenance, though certain issues appear with higher mileage or neglected service schedules. Oil consumption represents a common complaint in some 4B-series engines, particularly when maintenance intervals extend beyond recommendations. Keeping up with oil level checks and using quality synthetic oil meeting Mitsubishi’s specifications helps minimize consumption and protects internal components.

Timing belt maintenance proves critical for engines using belt-driven camshafts. Mitsubishi typically recommends replacement every 60,000 to 100,000 miles depending on model and year. Failure to replace worn timing belts can result in catastrophic engine damage, as most Mitsubishi engines feature interference designs where pistons and valves occupy the same space at different times in the combustion cycle. A broken timing belt allows these components to collide, causing extensive damage typically requiring complete engine replacement.

Turbocharger maintenance requires particular attention in forced-induction Mitsubishi engines. Turbos generate extreme heat and operate at tremendous speeds, making proper oil quality, cool-down periods, and routine inspection essential for longevity. Modified engines running increased boost pressure face accelerated turbocharger wear, requiring more frequent inspection and potentially upgraded components. Ignoring turbocharger maintenance warnings like excessive smoke, unusual noises, or boost pressure fluctuations can lead to catastrophic failures damaging the engine itself.

Evaluating Engine Replacement Necessity

Determining whether engine problems warrant replacement versus repair requires honest assessment of damage extent and repair costs. Minor issues like valve cover gasket leaks, sensor failures, or intake manifold problems typically justify repair rather than replacement. However, serious internal damage including scored cylinders, cracked blocks, or bearing failure usually makes replacement more economical than rebuilding, particularly when considering labor costs for complete engine disassembly and reassembly.

Calculating total cost-benefit including vehicle value, remaining useful life, and replacement alternatives helps frame decisions. An engine replacement might represent significant expense initially, but spreading that cost across years of continued use often proves more economical than purchasing a replacement vehicle with unknown history and potentially hidden issues. Vehicles with excellent body condition, maintained suspension and braking systems, and clean interiors justify engine replacement investments that restore them to reliable service.

Modified Mitsubishi vehicles, particularly performance variants like Lancer Evolutions or Eclipse Turbos, warrant special consideration. These enthusiast-oriented vehicles often carry emotional value beyond pure economics, and their increasing collectibility supports replacement investments. Additionally, finding replacement vehicles with similar specifications, conditions, or modifications becomes increasingly difficult as these vehicles age, making engine replacement attractive for preserving unique examples.

Benefits of Imported Japanese Engines

Japan’s automotive culture and regulatory environment create exceptional opportunities for Mitsubishi owners seeking replacement engines. The country’s comprehensive vehicle inspection system becomes increasingly expensive as vehicles age, encouraging owners to replace relatively new vehicles rather than invest in continued compliance. This cultural practice results in imported JDM Mitsubishi engines with 40,000 to 70,000 miles entering export markets, offering excellent alternatives to domestic salvage yard options with unknown histories and potentially higher mileage.

Japanese driving conditions generally promote engine longevity compared to typical North American use. Excellent highway infrastructure, comprehensive public transportation reducing commute stress, and generally moderate climate conditions create favorable operating environments. Most Japanese drivers operate vehicles conservatively, avoiding aggressive acceleration and high-speed driving that accelerate component wear. The cultural emphasis on preventive maintenance means Japanese vehicles typically receive regular oil changes, timing belt replacements, and scheduled service throughout ownership.

Quality control in Japan’s used automotive parts industry maintains high standards through competition and reputation management. Suppliers must provide accurate information about component condition, mileage, and operational history to maintain customer trust in a competitive marketplace. Many JDM engines arrive with compression test documentation, exterior photographs, and detailed specifications allowing informed purchasing decisions. This transparency contrasts sharply with typical domestic salvage yards where information about engine condition, history, or mileage often lacks reliability.

Selecting Quality Replacement Engines

Evaluating potential replacement engines requires attention to multiple factors beyond simple availability and price. Mileage represents an obvious consideration, though Japanese engines with 60,000 miles often show less wear than domestic equivalents with identical mileage due to superior maintenance and operating conditions. Compression test results provide objective data about internal condition, with consistent readings across cylinders indicating healthy engines while variations suggest potential problems.

Visual inspection reveals important information about engine care and storage. Clean exterior surfaces without excessive oil residue suggest proper maintenance and careful storage. Intact sensors, electrical connectors, and accessories indicate complete engines requiring minimal additional parts for installation. Corrosion on exterior surfaces or electrical components may signal improper storage conditions or extended exposure to moisture, potentially compromising reliability.

Warranty coverage demonstrates supplier confidence in product quality while providing protection against unexpected failures. Comprehensive warranties covering specific periods and mileage offer peace of mind, though understanding coverage limitations and exclusions prevents misunderstandings. Some suppliers provide extended warranties for additional fees, which may justify costs for expensive or rare engines where replacement difficulties would compound failure inconvenience.

Installation Considerations and Best Practices

Successful engine replacement requires careful planning, proper tools, and mechanical expertise or professional installation services. Mitsubishi engines integrate with sophisticated electronic systems controlling ignition timing, fuel injection, variable valve timing, and emissions equipment. Proper connection of sensors, wiring harnesses, and control modules ensures reliable operation and prevents diagnostic trouble codes or performance issues. Modern engine management systems may require programming or adaptation procedures after installation, necessitating access to appropriate diagnostic equipment.

Supporting component replacement during engine installation maximizes investment protection and prevents premature failures. Timing belts or chains, water pumps, thermostats, and coolant hoses represent relatively minor expenses during engine replacement but prevent future failures requiring additional labor costs. Engine mounts, transmission mounts, and accessory brackets should be inspected and replaced as needed to ensure proper alignment and vibration control. Using fresh fluids meeting Mitsubishi specifications, including appropriate oil weight and coolant type, provides optimal protection from initial startup.

Compatibility verification prevents costly mistakes and installation complications. Mitsubishi sometimes uses similar engines across multiple models with variations in accessories, sensors, or management systems. Confirming engine codes match between original and replacement units helps ensure proper fitment and functionality. Checking for differences in emissions equipment, intake manifold design, or exhaust routing prevents surprises during installation. Some engine swaps may require custom solutions for mounting, cooling, or accessory drives, increasing complexity and expense beyond basic replacement.

Long-Term Success Through Proper Maintenance

Establishing appropriate break-in procedures helps replacement engines achieve maximum longevity and performance. Avoiding full-throttle acceleration, sustained high-speed operation, and excessive idling during the first 500 to 1,000 miles promotes proper ring seating and bearing surface development. Varying engine speeds and loads while avoiding constant RPM operation helps components develop appropriate wear patterns. Early oil changes at 500 miles and 1,500 miles remove initial wear particles and manufacturing residues that can accelerate component degradation.

Implementing comprehensive maintenance schedules protects the investment in engine replacement. Following Mitsubishi’s recommended service intervals for oil changes, air filter replacement, and cooling system maintenance prevents premature wear and expensive repairs. Quality synthetic oils meeting Mitsubishi specifications provide superior protection, particularly for turbocharged engines generating extreme heat and stress. Premium filters for oil, air, and fuel protect expensive components from contaminants causing accelerated wear or failure.

Monitoring engine performance through observation and periodic diagnostic checks helps identify developing issues before serious damage occurs. Unusual noises, changes in oil consumption patterns, coolant loss, or performance degradation warrant immediate investigation. Modern diagnostic equipment can detect sensor anomalies and developing problems through data analysis before physical symptoms become apparent. Addressing minor issues promptly prevents cascade failures that can destroy replacement engines as thoroughly as original units, protecting both financial investment and continued vehicle reliability.

Engine replacement represents a significant commitment to vehicle longevity, particularly for well-maintained Mitsubishi vehicles with excellent overall condition. Understanding available options, selecting quality components from reputable sources, and maintaining engines properly through appropriate service ensures years of continued reliable performance, making replacement a sound investment in preserving the driving experience and utility that attracted owners to Mitsubishi vehicles originally.